低濃度瓦斯發(fā)電氣體的傳輸安全性能

低濃度瓦斯發(fā)電在實際應用中需要幾種核心技術來支撐整個發(fā)電過程的順利進行,如可靠性高的阻火技術、全電子控制技術、電控燃氣混合器技術、數字式點燃技術以及瓦斯與空氣混合增壓技術等。在整個機組系統(tǒng)中,首先要保證運行和氣體傳輸的安全性,因此需要設置安全可靠的阻火器,在發(fā)電站總進氣管、機組進氣總管、混合器前的燃氣管線、中冷器與增壓器之間及進氣管調速節(jié)氣門間都需分別安裝不同類型的阻火器。

In practical applications, low concentration gas power generation requires several core technologies to support the smooth progress of the entire power generation process, such as reliable flame retardant technology, fully electronic control technology, electronically controlled gas mixer technology, digital ignition technology, and gas air mixed turbocharging technology. In the whole unit system, the safety of operation and gas transmission must be ensured first, so safe and reliable flame arresters need to be set. Different types of flame arresters need to be installed respectively in the main air intake pipe of the power station, the main air intake pipe of the unit, the gas pipeline in front of the mixer, between the Intercooler and the supercharger, and between the speed regulating throttle of the air intake pipe.

另外,在瓦斯輸送時不僅需要保證輸送管道不漏氣、不易燃,還需配置細水霧輸送裝置。安置數量由輸送管道長度和輸送瓦斯規(guī)模等多方面因素決定。

In addition, when transporting gas, it is not only necessary to ensure that the conveying pipeline is not leaking or flammable, but also to equip a fine water mist conveying device. The number of placements is determined by various factors such as the length of the transmission pipeline and the scale of the gas transmission.

電控燃氣混合器技術,簡言之,就是通過電工藝與技術子控制技術來調節(jié)混合氣的混合比例和空燃比,而瓦斯與空氣混合增壓技術則是需要增壓器和中冷器來促進瓦斯空氣的混合效果和混合比例,提高發(fā)電機功率并降低產生的熱負荷。發(fā)電技術在不斷改善,目前點火技術上多用電控單元來根據實際情況調控點火時間、點火強度等,確保點火操作處于的環(huán)境中。

In short, the technology of electrically controlled gas mixer is to adjust the mixing ratio and air-fuel ratio of gas mixture through electrical process and technical sub control technology, while the technology of gas air mixed pressurization requires supercharger and Intercooler to promote the mixing effect and mixing ratio of gas air, increase the power of generator and reduce the generated heat load. The power generation technology is constantly improving. Currently, electronic control units are commonly used in ignition technology to regulate ignition time, ignition intensity, etc. based on actual conditions, ensuring that ignition operations are in the optimal environment.

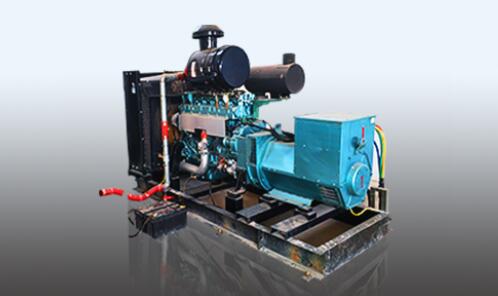

低濃度瓦斯發(fā)電技術經研發(fā)和不斷創(chuàng)新之后在我國大部分煤礦中得到應用,在其所有應用形式中,燃氣內燃機式發(fā)電優(yōu)勢,其他還有鍋爐與蒸汽輪機發(fā)電模式、燃氣輪機與蒸汽輪機發(fā)電組合模式。在使用瓦斯發(fā)電時,燃氣內燃機式發(fā)電模式具有燃燒充分完全、排放有害氣體少、抗爆燃性能好、經濟效益高和混合氣發(fā)火范圍廣等絕對性優(yōu)勢。

After research and continuous innovation, low concentration gas power generation technology has been applied in most coal mines in China. Among all its application forms, gas internal combustion engine power generation has the most advantages, and other power generation modes include boiler and steam turbine power generation mode, gas turbine and steam turbine power generation combination mode. When using gas for power generation, the gas internal combustion engine power generation mode has absolute advantages such as complete combustion, less harmful gas emissions, good anti knock performance, high economic benefits, and a wide range of mixed gas ignition.

本文由瓦斯發(fā)電機組友情奉獻.更多有關的知識請點擊: http://www.kan138.cn真誠的態(tài)度.為您提供為全面的服務.更多有關的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is dedicated to the friendship of gas generator units. For more relevant knowledge, please click on: http://www.kan138.cn Sincere attitude. We will provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Stay tuned

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當前位置:

當前位置: 2023.07.10

2023.07.10